by GDS Team | Jul 30, 2021 | Toxic Gas

Whether you have a confined space in an oil refinery, a production area in a manufacturing plant, or a laboratory in a medical research facility, a toxic gas buildup can happen at any time. This danger is a major concern for large facilities, but there’s a solution....

by GDS Team | Jul 9, 2021 | Toxic Gas

The number of warehouses in America is increasing steadily year by year. As more and more warehouses are being built, the need for safety programs can’t be underestimated due to the toxicity of chemicals used on a regular basis. Discover the difference between the...

by GDS Team | Nov 6, 2020 | Electrochemical Sensors, Toxic Gas

Carbon dioxide (CO2) is an odorless colorless gas that is present in the atmosphere in small quantities, typically 400 parts per million or less. CO2 is generated by industrial processes that include the burning of fossil fuels for heat, power, and transportation and...

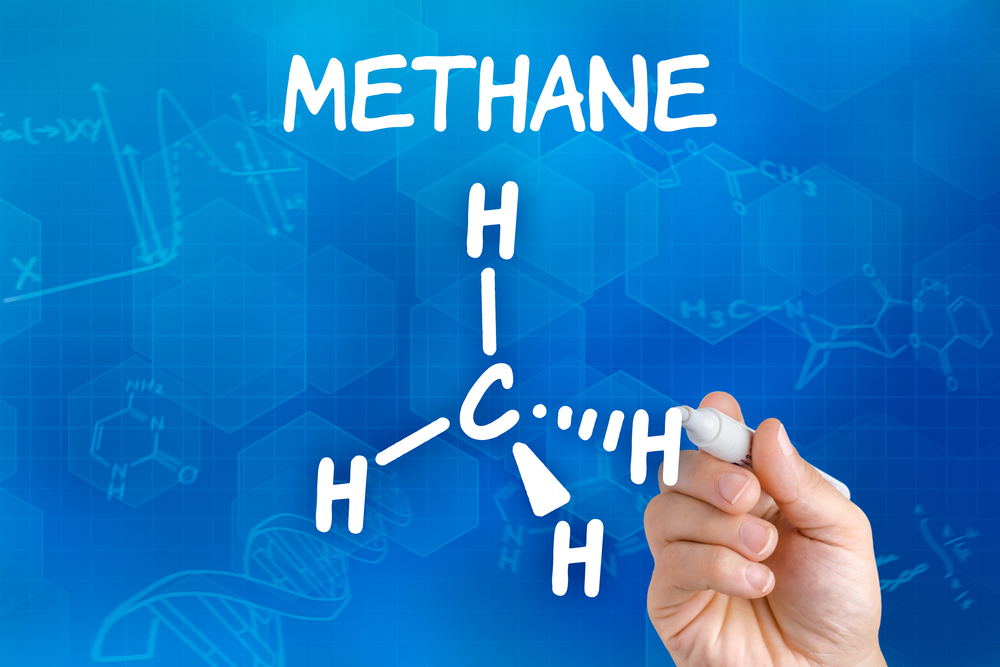

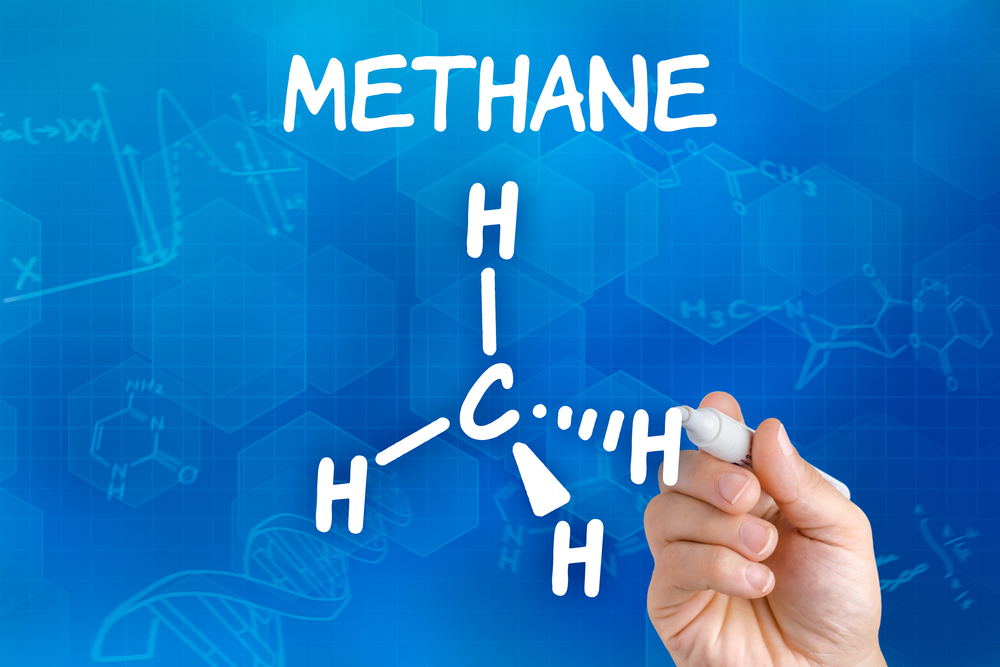

by GDS Team | Jun 19, 2020 | Catalytic & Infrared Sensors, Methane Gas Detectors, Toxic Gas

Choosing the right gas sensor for your fixed detection system involves a number of considerations, especially when detecting methane gas. Between the different types of sensors on the market, there are two different technologies to consider: infrared and catalytic...

by GDS Team | Apr 10, 2020 | Combustible Gases, Dual Channel Detectors, Toxic Gas

In manufacturing facilities or environments where hazardous materials are present, there are often a number of gases that need to be monitored. Understanding dual-channel gas detectors are essential to ensure that you have the most cost-effective gas detection system...

by GDS Team | Apr 3, 2020 | Gas Emission, Toxic Gas

Every manufacturing industry, from oil and gas to chemical production, deals with various types of toxic gas. Maintaining healthy levels of these dangerous gases is essential to protect the wellbeing of employees and warehouse workers. Depending on the concentration...