by GDS Team | Jun 19, 2020 | Catalytic & Infrared Sensors, Methane Gas Detectors, Toxic Gas

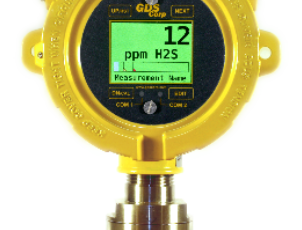

Choosing the right gas sensor for your fixed detection system involves a number of considerations, especially when detecting methane gas. Between the different types of sensors on the market, there are two different technologies to consider: infrared and catalytic...

by GDS Team | Mar 27, 2020 | Catalytic & Infrared Sensors, Combustible Gases

Do you regularly work with combustible gases? From fuel sources such as methane and propane to heavier hydrocarbons such as ethane and propylene, combustible liquids and gases pose a number of risks for your facility. Understanding the technology behind detecting...

by GDS Team | Mar 11, 2017 | Catalytic & Infrared Sensors

Whether it’s a refinery, manufacturing plant, or water treatment plant where high levels of dangerous gases may be present, it’s important to have sensors that are able to alert personnel to danger at a moment’s notice. In these work environments,...

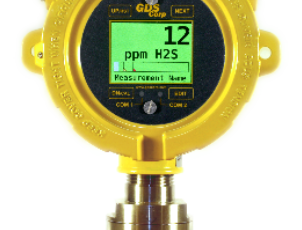

by GDS Team | Apr 1, 2016 | Catalytic & Infrared Sensors

There are a wide range of gas sensor products available; which type you use depends on the working environment and what types of gas might be present, such as natural gas, carbon monoxide, or airborne organic compounds. Catalyst sensors are often used to detect...

by GDS Team | Dec 29, 2014 | Catalytic & Infrared Sensors

To detect combustible gases in industries, it is important to choose a safe, dependable and affordable solution. There are two main technologies involved; they are infrared (IR) sensors and catalytic sensors. Each method has its advantages depending on the...