Give Us a Call

Questions or Comments?

Understanding Infrared Receiver and Detection Systems

Infrared gas detection is a method for detecting combustible hydrocarbon gas with infrared light. The detector consists of a source of infrared light, an optical filter to select the proper wavelength and an optical infrared receiver. As the gas flows into the space between the source and receiver, hydrocarbon molecules in the gas absorb some of the infrared energy. The receiver detects this drop in received energy as a measure of the amount of hydrocarbon gas present. An Infrared Gas Detector often uses two wavelengths of infrared energy with one active wavelength used for gas absorption, and the other as a reference wavelength to compensate the output signal of the Infrared Gas Detection system for the effects of temperature, humidity and the presence of moisture or dirt on the optical filters.

Infrared gas detection devices may be classified as open path detection or point detection. Point devices, such as the GASMAX II or GASMAX CX measure the amount of gas present at a fixed location. Open path detectors such as the Quasar SafEye ® 900 include separate transmitters and receivers and measure the presence of gas between the two points up to 200 meters apart. In most cases, a combination of open path and point detectors can be combined to provide the highest level of safety.

Catalytic bead sensors have been replaced by gas monitors based infrared gas detection. This is because the infrared method is free of frequent calibration requirements, silicon poisoning and the need for oxygen to be present in order to detect hydrocarbon gases. As a result, infrared detectors have become more reliable for monitoring hydrocarbon within fixed gas detection systems. The microprocessor used in typical infrared gas detection systems continuously monitors the status of the source and receiver and communicates any errors or fault conditions to the controller, transmitter or other PLC and DCS system.

Since the infrared gas detection wavelength implemented in hydrocarbon detection is similar to that needed for carbon dioxide detection, these systems are also great for toxic and percent by volume monitoring of CO2.

Contact GDS Corp. for Passive Infrared Detection and More

If you want a safe, reliable, cost effective and easy to use infrared gas detection system, count on GDS Corp. to deliver. Our application engineers are available Monday through Thursday from 8am to 5pm, and from 8am to Noon on Friday. Call today!

Featured Products

GDS Gas Detection Products

Our CSA and ATEX certified fixed and transportable gas detectors, gas sensors, flame detectors and alarm and display controllers are truly ‘state of the art’ devices offering unparalleled features and capabilities.

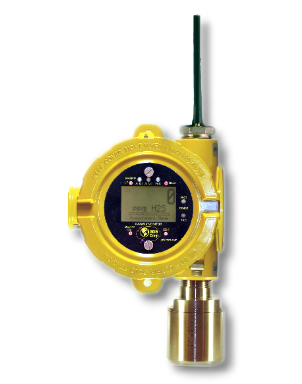

GASMAX CX

SINGLE / DUAL CHANNEL GAS MONITOR

More Information

Gasmax TX

WIRELESS DUALCHANNEL TOXIC COMBUSTIBLE GAS MONITOR

More Information

GDS IR

More Information

GDS-58NXP

More Information

Information Request Form

Complete this form to receive information specific to your needs.