Our industrial and commercial clients work in the oil and gas, water and waste water, semiconductor, chemical processing, offshore, marine, municipal, utility and other industries. We are able to create systems for large and small businesses alike, and always take the time to understand your goals. We concentrate on reliability, cost effectiveness, and ease of use and, of course, safety. These things have made us and our state of the art technology leaders in the combustible gas sensor field.

Give Us a Call

Questions or Comments?

Creating Custom Combustible Gas Sensors For Your Company

Combustible gas is always present as a hazard in most industrial and commercial manufacturing facilities. Methane, propane, hydrogen and natural gas are the most common combustible gases, but even gases such as carbon monoxide are combustible in high concentrations.

Combustible gas detectors measure their environment in 0-100% LEL or percent of Lower Explosive Limit. The LEL value for any combustible gas is the percent that must be present in ambient air for an explosion to take place. For example, the LEL level for methane is 5% by volume, and the presence of 2.5% by volume in the air sample would generate a reading of 50% LEL on a properly calibrated gas detector.

Combustible gas sensors for hydrocarbons, such as methane and propane, can be based on either catalytic bead sensors or infrared sensors. Catalytic bead sensors detect the gas by actually burning gas molecules on one of the sensor elements, which results in additional heating and a subsequent increase is electrical output. Infrared detectors take advantage of the fact that hydrocarbon gas absorbs infrared light at specific frequencies. When gas passes between the infrared source and receiver, the receivers output drops and the microprocessor (inside the sensor) generates an output proportional to the amount of absorption.

Both types of sensors have advantages and disadvantages. Catalytic bead sensors are low cost, simple and reliable, but their sensing elements are exposed to the atmosphere and are subject to temporary or long term poisoning by certain silicon or halogen-based compounds that may be present. Infrared sensors remain in calibration longer and offer the ability to provide self-test capability, but cannot detect non-hydrocarbon gases such as hydrogen.

Call GDS Corp Now To Learn More About Combustible Gas Sensors

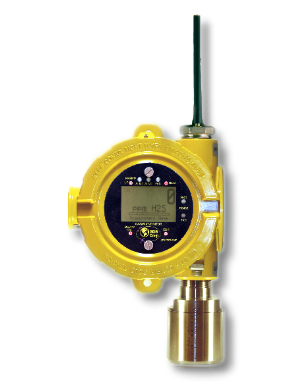

GDS Corp offers both catalytic bead and infrared sensors calibrated for a number of different combustible gases. When you’re ready to talk to us about the combustible gas sensor your industrial company needs, feel free to use the inquiry contact form on our site, or call one of the many phone numbers listed on our contact page. Our staff and application engineers look forward to speaking with you!

Information Request Form

Complete this form to receive information specific to your needs.

"*" indicates required fields