Gas detection is a crucial part of the safety regimen for oil companies. Early detection means finding and repairing a leak or problem quickly cutting down on the possibility that a leak could cause a major accident or hazard. Having the right equipment is the first step, and making sure the testing procedure and correct timeline of testing is accurate, is equally as important.

Why Are Gas Detectors Important?

On oil rigs, there are a many emission concerns and considerations. Different types of gas emission, such as toxic, combustible or volatile gases, can create hazards both for workers as well as organisms living in the surrounding habitat or close by communities. The question for safety engineers and those testing for pollutants or hazardous gas is how much might be leaking out and where. Combustible gas causes the greatest threat and can cause major damage. Not only is the right detector system for oil rig extraction important, the location points are just as integral to the system functioning well.

Impact of Poorly Functioning Detectors

In the case of traditional diffusion sensors, where high moisture or high temperature scenarios can create faulty readings or shut down the sensors, a rig and its workers is greatly compromised. When this occurs, exact toxicity is unknown, causing a greater threat to the environment or workers. Systems with the latest technology in sensors, like remote sensor reading capability, or those that can withstand high impact temperature or flow, make the most sense on rigs. Those that can detect trace amount of toxicity, from combustible hydrocarbons to carbon dioxide, are an optimal choice.

Cost Benefit of Proper Gas Detection on Oil Rigs

Unfortunately, we need not look farther than recent events to understand how investing in the right equipment and the right maintenance and upkeep makes the most sense. First, a central system protector is an industry standard today throughout the world in offshore rigging. It provides the most reliability, with a testing spectrum of over 60 crucial variables when testing. Investment in the proper oil rig detectors is insurance against the worst-case scenario, and the correct set-up provides ease of use in both remote and traditional analog monitoring.

Choosing the Right Detectors for Oil Rig Safety

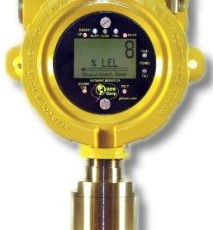

A combination of both fixed and remote or portable detectors comprise a functional detection system. Detectors that test toxicity levels, flow pressure, valve functioning and that have a connected back-up system in the event of a power lapse are crucial parts of the overall system. Calibrating detection systems and devices and ensuring their functioning properly should be a standard part of the system. Daily challenge and bump tests of each part of the system are imperative here so that detectors are working properly.

Gas detection on oil rigs is a costly, rigorous process that should be followed daily and with acute attention to detail in readings and monitoring. It should comprise a healthy percentage of the management requirement on oil rigs insuring the safety of workers and surrounding communities.