Welcome To GDS Corp

High quality gas detection is a critical factor in the safe operation of your company and protection of your staff and clients. At GDS Corp, we understand the importance of reliable, cost-effective gas detection systems and specialize in solutions for the most challenging work environments.

Product Catalog

- Odorant Monitors

- Sample Draw Monitors

- Open Path Gas Detectors

- Flame Detectors

- Power Systems

- Calibration Supplies

Odorant Monitors

Odorant Monitors sample the level of hydrogen sulfide or mercaptan-based odorants in streams of natural gas. Maintaining an acceptable level of odorant is critical to the safe operation of natural gas distribution systems.

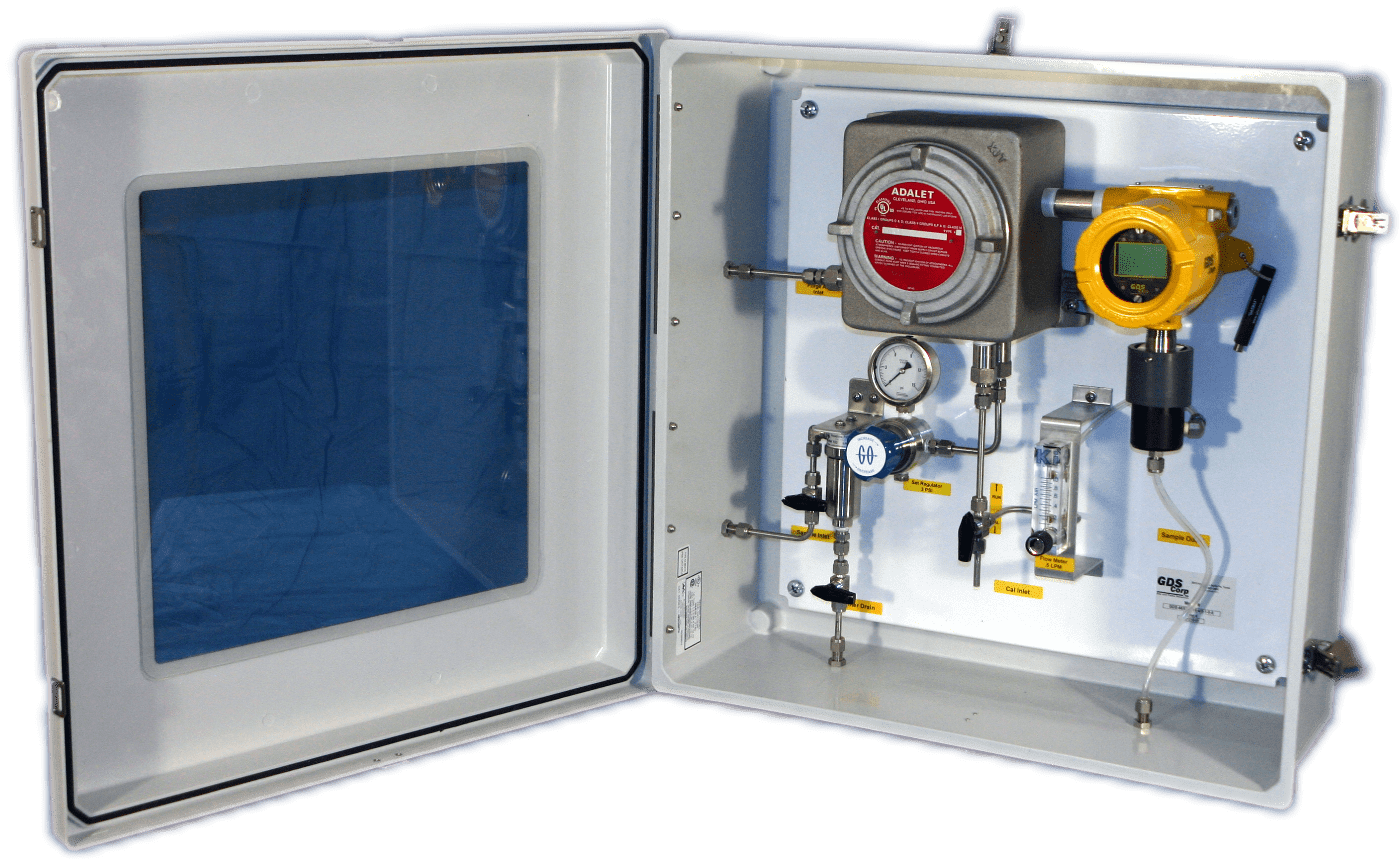

Sample Draw Monitors

In some enclosed applications, installing a gas sensor is impractical, dangerous, or creates a calibration nightmare. Sample Draw Monitors solve this problem by pulling a continuous sample of gas into the monitor using a long-life sample pump.

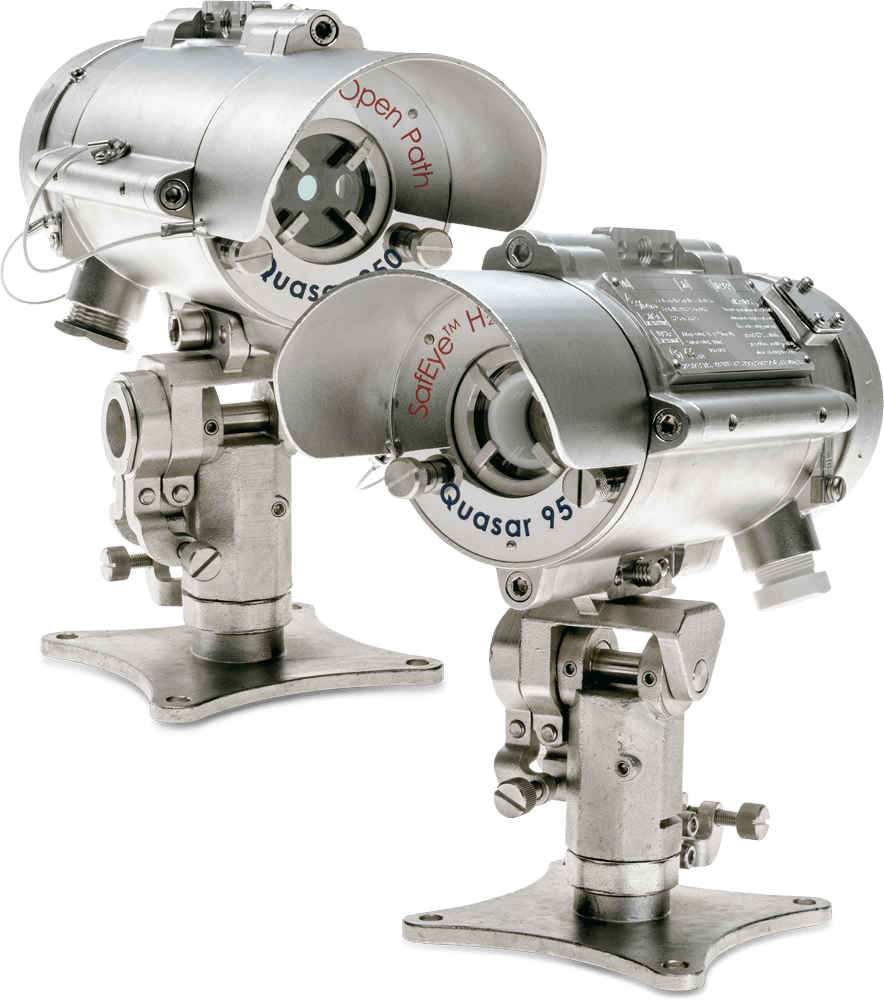

Open Path Gas Detectors

Open Path Gas Detectors use high intensity infrared light to detect the presence of hydrocarbon gases that pass between the transmitter and receiver. When used in conjunction with fixed monitors, Open Path detectors can provide an extra level of safety for fence lines and other linear boundaries.

Flame Detectors

Flame Detectors are designed to send an alarm if any open flame is detected in an industrial environment. Flame detectors monitor infrared and ultraviolet wavelengths and use sophisticated signal processing techniques to minimize false alarms.

Power Systems

Gas detection systems operated at peak effectiveness when provided with a source of reliable, low-noise DC power. Selection of the proper Uninterruptible Power Supply (UPS) or Solar Power System is critical for gas detection systems operated in remote or noisy environments.

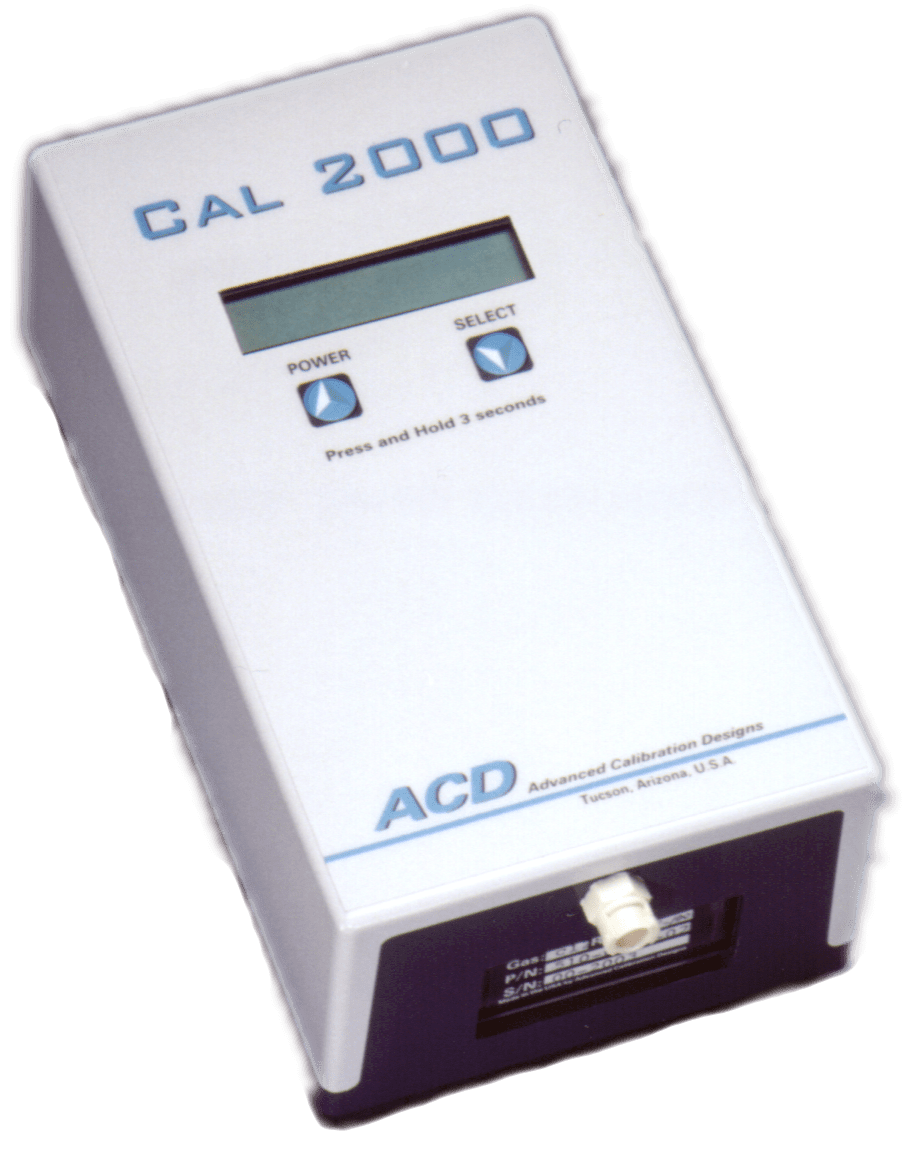

Calibration Supplies

Periodic calibration is critical to the continued safe operation of any gas detection system. GDS Corp offers calibration kits, reference gas cylinders and calibration gas generators for all applications.

Read Our Blog

5 Reasons Why Your Ammonia Detector Isn’t Working Properly

Working with ammonia gas in refrigeration systems or industrial equipment comes with a number of...

5 Reasons Why Your Ammonia Detector Isn’t Working Properly

Working with ammonia gas in refrigeration systems or industrial equipment comes with a number of...

Ready to get started?

Fill out a contact form to begin your gas detection project.